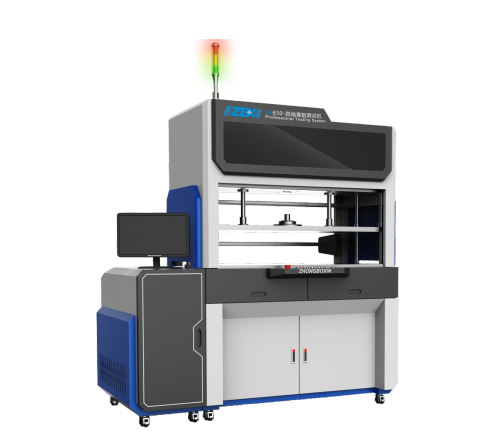

Manual four-wire milliresistance tester

Manual four-wire milliresistance tester

Product Feature

* Measure resistance in milliohms, with high test accuracy

* Effectively measure line width/copper thickness and hole breakage to ensure product quality

* Four-wire fixture can be set at any point

* Two-wire and four-wire can complete the test at one time

* 2-wire test speed: 5000 points/sec

* Four-wire test speed: 700 groups/sec

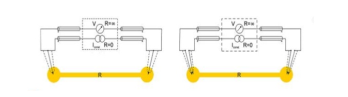

Four-wire electrical test principle

* The four-wire electrical test is specifically used to test the resistance of very small internal vias. It is also called the four-terminal resistance measurement method. It can accurately measure low resistance without contact with lead points or resistive properties.

* The four-wire electrical test is divided into two parts. The first part of the test produces a fixed current, the second part of the test measures the voltage. Since no current flows in the second part of the test, the resistance of the contact will be cancelled out.

* The "true resistance value" is accurately calculated through the through-hole measurement.

* In the traditional single-probe test, only one wire and one probe are connected. For the four-wire electrical test, the double probe needle will have two wires connected to the two probe tips respectively.

| Manual four-wire milliresistance tester | |

| Testing area | 500mm * 800mm |

| Testing Points | 2048-20480 Points |

| Testing Speed | ≥ 5000 p/s (2-wire test) ≥ 700 net/s (4-wire test) |

| 2-wire continuity test | 10Ω-20KΩ |

| 4-wire continuity test | 1mΩ-100Ω |

| Test logic | 2-wire & four-wire compelete testing synchronously and quickly 1M-500MΩ (100MΩ Optional) |

| Test Voltage | 20V-250V |

| Test Current | Max. 50 mA |

| 4-wire continuity test accuracy | 1mΩ±10% |

| Power Requirement | AC220V/50HZ ±10% 10A |

| Voltage supply | 0.6-0.8 Mpa(Dry and clean) |

| Temp. & Humidity | 22℃-25℃ 40%-60% |